Machine vision systems can help manufacturing companies save money in a number of ways. Get in touch with our machine vision experts to estimate the cost of your project and its return on investment :

- Reduced labor requirements

- Reduction of false rejects and manufacturing defects

- Reduced purchases of mechanical equipment

Vision Inspection project evaluation

Our team will estimate the feasibility and costs associated with implementing an automated solution to solve your inspection problems.

Cognex DataMan 70 series

Cognex DataMan 150/260 series

In-Sight 2800 Séries

In-Sight 7000 Series

In-Sight 9000

In-Sight 2000 Vision Sensors

DataMan 280 Series

DataMan 370 series

DataMan 470 series

In-Sight 8000

In-Sight 5705

In-Sight D900

In-Sight 2000 Mini Vision Sensors

Dataman 8050 Series

Dataman 260 Series

Dataman 8600 Series

Dataman 7500 Series

Dataman 300 Series

Dataman 8700 Series

Cognex Dataman Series

Dataman 7500

Dataman 8500 Series

Dataman 374 Series

Dataman 500 Series

Dataman 50-60 Series

Dataman 150 Series

Dataman 8000 Series

Dataman barcode scanner

Cognex Dataman 360 Serie

3d machine vision camera

cognex handheld scanner

Cognex edge intelligence

2D Vision Systems

Cognex In-Sight 3800

What are vision systems?

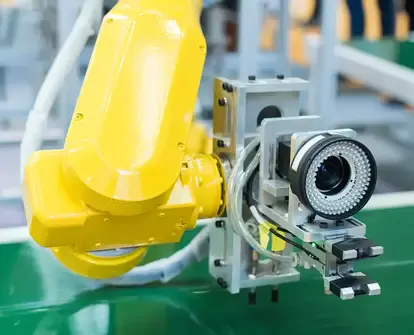

A machine vision system is an automated visual inspection machine used to capture and analyze images to recognize defects, classify products or materials, and automatically inspect objects. Machine vision integrates multiple systems that together can be used in many applications such as quality control, automated guided vehicles, and assembly systems.

What are the different types of vision systems?

There are different types of machine vision systems, depending on the type of camera and how the system is used. Machine vision can use different types of cameras, including digital cameras, standard analog cameras, and linescan cameras. The type of camera and how it is used determines the types of processing needed after the camera captures an image.

How does a vision system works?

A machine vision system is a device specifically designed to detect objects, measure their attributes and shape, or determine the location or orientation of those objects. To perform these tasks, a machine vision system needs three components: an image capture device with lenses and filters; an image processing unit for converting the images into meaningful information; and finally, an output display to show you the results. Most machine vision systems also have some type of computer interface (eg Ethernet) so that they can be connected to other devices such as programmable logic controllers (PLCs) or industrial PCs.

Which industries uses vision systems?

Machine vision systems are used in many industries, including industrial manufacturing, medical imaging devices, automated guided vehicles, safety equipment, and robotics. Most industrial applications use vision systems to solve a specific problem in various industries.