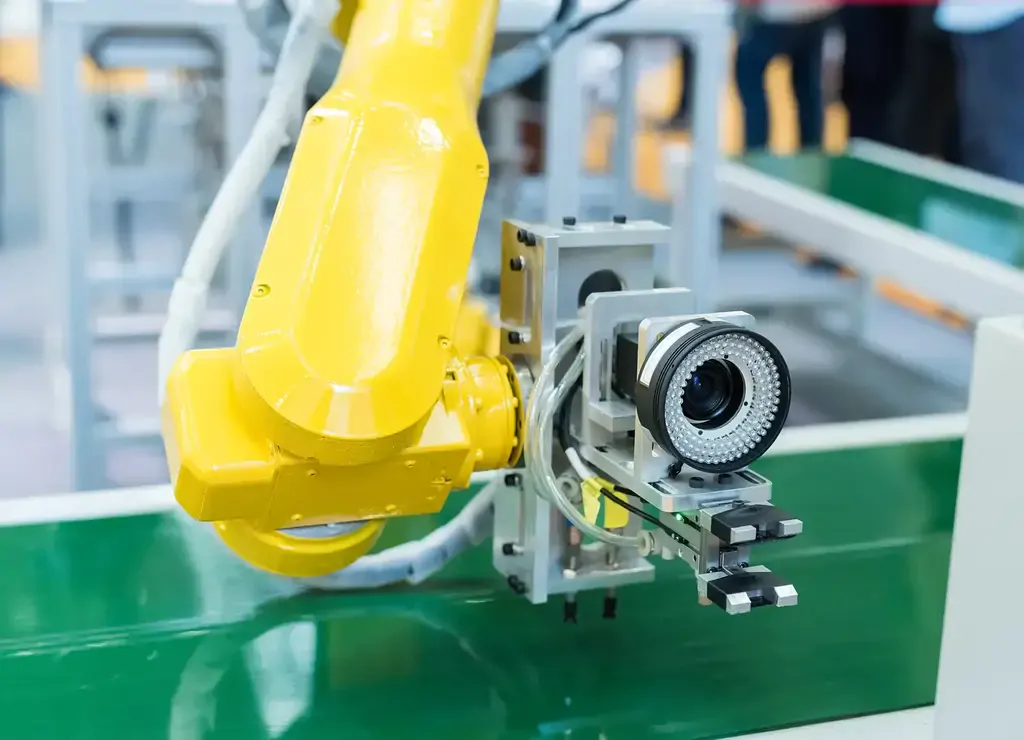

Automated vision inspection systems is providing image-based inspection for a variety of industrial and manufacturing applications. These systems use advanced imaging technology, including cameras, sensors, and image processing software, to automatically inspect products or components for defects or deviations from pre-set criteria.

At Mécatronique Solutions, we understand that automated vision inspection systems and robotics are essential in maintaining product quality, efficiency, and safety across various industries.

Importance of Default Values in Automated Inspection Systems

In the world of Automated Vision Inspection (AVI) and machine vision systems, default values play a critical role particularly in industries such as food and pharmaceutical industries where stringent quality control standards are essential.

They ensure that the system continues to function correctly even when certain parameters aren't explicitly defined.

For instance, if the vision system is scanning an object and the user doesn't specify a certain parameter, the system can fall back on a default value, ensuring smooth operation.

This is especially crucial in other applications like label inspection, where accuracy is paramount, and in the development of a unique vision system tailored to specific production line requirements.

Applying Default Values in Database Management

Database management is another area where default values are key. They provide a safety net for data entry, ensuring that every field in a database has a value.

This helps the companies maintain data consistency and integrity, crucial for reliable data analysis and decision-making processes.

Enhancing Automated Vision Inspection System with Default Values

At Mécatronique Solutions, we leverage default values in our AVI systems to enhance performance and reliability. By setting sensible defaults, we ensure that the system can handle a wide range of scenarios, increasing its versatility and robustness.

This allows us to deliver high-quality inspection solutions that meet our clients' diverse needs.

Use of Default Values in Various Coding Languages

Default values are a crucial aspect of programming languages when developing automated vision and automated visual inspection systems, (AVI) systems.

Different coding languages offer mechanisms for setting default values, allowing developers to establish predefined configurations for various parameters.

In Python, for instance, default parameter values can be easily defined within function declarations, facilitating the initialization of parameters such as image processing filters or visual inspection thresholds.

Pros and Cons of Using Default Values in Software Development

At Mécatronique Solutions, we believe in providing a balanced and integrated view of all aspects of programming. Hence, we acknowledge that while default values offer numerous benefits, they also come with potential drawbacks.

On the upside, they can significantly simplify coding and streamline the development process.

Pros :

-

Default values can significantly simplify coding and streamline the development process.

-

Especially beneficial in automated vision inspection systems, where default values reduce the time consumed in assigning individual values.

Cons :

-

Using default values indiscriminately can lead to errors and confusion, particularly in complex systems.

-

In systems involving artificial intelligence algorithms and optical character recognition, incorrect default values can propagate throughout the system and cause unexpected outcomes.

Best Practices for Using Default Values in Programming

At Mécatronique Solutions, we encourage prudent use of default values in programming. Developers should only use default values when they bring clear benefits and reduce the potential for errors.

It's crucial to document all default values to prevent confusion and facilitate troubleshooting.

In addition, as a best practice, developers and software tools should always provide an easy way to override the default values to accommodate unique circumstances or system requirements.

Optimizing Machine Vision Systems with Default Value Best Practices

In automated vision inspection systems, following these best practices can dramatically improve system performance and reliability.

By carefully choosing and documenting default values, developers can make the system more intuitive and easier to operate. This can lead to :

-

Faster setup

-

Fewer errors and defects

-

Higher product quality and yield

Common Mistakes to Avoid When Setting Default Values

When setting default values, it's crucial to steer clear of common pitfalls:

-

Overreliance: Don't rely too heavily on default values; consider specific needs.

-

Lack of User Input: Ensure users can override defaults for flexibility.

-

Poor Documentation: Thoroughly document default values to prevent confusion.

-

Failure to Update: Keep defaults up-to-date with evolving requirements.

-

Inconsistent Values: Maintain consistency across system components.

By avoiding these mistakes, developers can optimize default value usage, ensuring smoother system operation and maintenance.

How Default Values Improve Efficiency in Database Systems

Optimizing Efficiency in Automated Vision Inspection Systems

At Mécatronique Solutions, we believe in the power of default values to enhance efficiency in database systems. Default values significantly reduce the amount of data entry required by users.

For instance, when performing tasks such as data insertion or record creation, default values ensure that certain fields are automatically filled, saving time and reducing the likelihood of errors.

Streamlining Operations Through Default Values in Database Systems

In the context of automated vision inspection systems, default values can be used to set parameters like image resolution, lighting conditions, or inspection speed.

This means the system can immediately start processing images using these preset conditions, enhancing operational efficiency.

Furthermore, default values ensure consistency across multiple inspection systems, promoting uniformity in data analysis, production, and interpretation.

Boosting Efficiency in AVI Systems with Default Values

Default values are instrumental in boosting efficiency in automated vision inspection (AVI) systems by minimizing setup complexity and maximizing operational robustness.

By establishing default settings for key parameters such as image processing algorithms, defect detection thresholds, and camera exposure settings, AVI systems can effortlessly adjust to different inspection demands.

This adaptability streamlines the manufacturing process, system deployment, and maintenance, ultimately improving overall production efficiency and reducing operational costs.

Effective Use of Default Values in Mécatronique Solutions

In a practical application, our client, Mécatronique Solutions, successfully leveraged default values in their automated vision inspection systems. Mécatronique Solutions had to inspect thousands of components daily, which required consistent and efficient automation systems.

By setting default values for inspection parameters, they were able to automate the inspection process further, reducing manual input and the potential for errors. This resulted in :

-

Increased productivity

-

Consistent data collection

-

Quality control and streamlined analysis processes

The success of Mécatronique Solutions reaffirms our belief in the potential of default values in improving the quality and efficiency of inspections using automated vision inspection systems.

Mécatronique Solutions' Use of Default Values in Automated Vision Inspection Systems

This strategic use of default values not only simplified system setup for clients but also enhanced the accuracy and speed of defect detection, resulting in superior product quality and increased manufacturing line throughput.

As a result, Mécatronique Solutions cemented their reputation as industry leaders in AVI technology.

Vision Inspection project evaluation

Our team will estimate the feasibility and costs associated with implementing an automated solution to solve your inspection problems.