Get product pricing

Cognex delivers the widest range of image-based factory automation and distribution products to help companies like you ensure error-free production, lower costs, and manage your supply chain

Innovative applications of machine vision systems in manufacturing process

Cognex' vision inspection systems are cutting-edge solutions that integrate advanced imaging technology, computer hardware, and machine vision algorithms to automate visual inspections and quality control processes in industrial settings.

These systems utilize high-resolution cameras, powerful software, computer hardware, and customized lighting setups to capture and analyze images or video streams of products or components, enabling automatic identification and verification of issues, measurements, and other quality parameters.

With a long-standing reputation as a leading provider of industrial vision systems, Cognex offers a wide range of solutions tailored to various manufacturing applications many industries.

These systems have revolutionized the way companies and industries approach quality control, streamlining industrial production processes to reduce costs and minimizing defects.

What is a machine vision system?

A Machine vision inspection system consists of several key electronic components working together to perform accurate and efficient inspections.

High-resolution cameras

At the heart of the whole vision inspection system are high-resolution cameras that perform image capture or video streams of the products or parts under inspection.

These cameras can be configured to capture light from multiple angles or for light in different spectral ranges, depending on the requirements of the application.

Specialized software

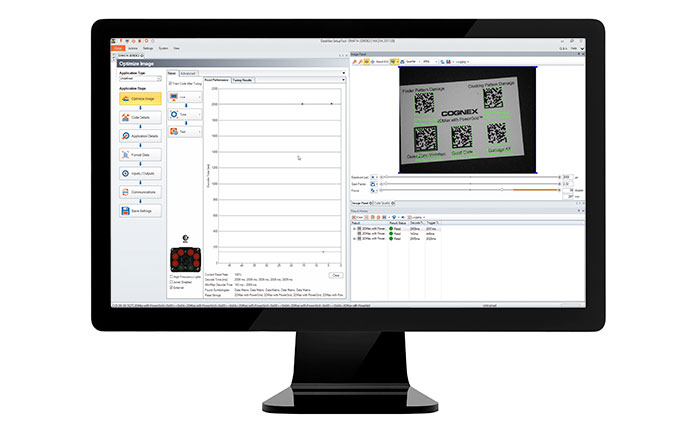

The captured images or video streams are then processed using specialized software, such as Cognex VisionPro, for example, which applies advanced algorithms for pattern recognition, image analysis, and defect detection.

The software compares the obtained images with predefined parameters, for example, allowing it to identify defects, measure dimensions, and perform other critical quality checks.

Lighting and optics

To ensure optimal image quality and visibility, machine vision systems make use of lighting and optics techniques.

These lighting, can include tailored illumination and light setups, such as ring lights or backlighting, to enhance contrast and highlight specific features for inspection.

Optics, such as lenses and filters, can be selected to meet specific field-of-view or magnification requirements.

Components of a machine vision system

Cognex optical vision inspection systems consist of various essential components that work together to enable precise and reliable system integration for inspections of defective automotive parts.

These components include cameras and sensors, image inspection equipment and software, and industrial cameras, lighting and optics setups.

Cameras

The cameras used in Cognex' optical system are high-resolution camera devices capable of capturing detailed images or video streams of the products or components being inspected.

These cameras come in different models, offering a range and combination of resolutions, frame rates, and camera interface options to suit the specific requirements of the application.

They are designed to provide exceptional image quality and clarity, ensuring accurate analysis and detection of defects.

Sensors

Sensors play a crucial role in Cognex optical systems, as they allow the system to perform at optimal levels.

These sensors can be proximity sensors, light sensors, or even temperature sensors, depending on the specific needs of the production line and environment.

By providing vital feedback and data, sensors enable the system to adapt and respond to changes in real-time, ensuring consistent and reliable performance.

Image processing software

Machine vision systems rely on advanced image processing software, such as Cognex VisionPro, to analyze snapped images or video streams.

This software offers a comprehensive set of tools and algorithms for image enhancement, pattern recognition, feature extraction, and defect detection.

It enables users to define inspection parameters, set tolerances, and configure specific measurement criteria to ensure accurate and efficient inspections.

Benefits of implementing a vision inspection system

Improved quality control

The implementation of machine optical systems brings forth numerous benefits to manufacturing industries, for example, revolutionizing industrial quality control processes and enhancing manufacturing efficiency.

One of the key benefits of implementing Cognex optical systems is the significant improvement in quality control.

High quality detection

These systems enable the detection of even the tiniest flaws and deviations in products or other electronic components themselves, ensuring that only items meeting the highest quality standards are passed through the manufacturing process.

With advanced algorithms and high-resolution cameras, machine vision systems offer exceptional accuracy and reliability in defect detection, reducing the risk of faulty products reaching the market and protecting brand reputation.

Increased efficiency in manufacturing processes

Machine vision systems streamline manufacturing processes by automating inspections and reducing the need for manual labor.

These vision inspection systems can perform multiple inspections together at high speeds, capable of analyzing thousands of parts per minute.

By eliminating the need for manual inspections defective parts, which are prone to errors and inconsistencies, Cognex' vision inspection systems optimize fabrication, improve efficiency further, reduce cycle times, and increase throughput. Manufacturers benefit from accelerated throughput rates, improved productivity, and reduced production costs.

Furthermore, machine vision systems can be seamlessly integrated into existing production lines, enhancing process efficiency and reducing the time consuming overall downtime.

The real-time feedback and operational guidance provided by industrial cameras within the system allows operational guidance for immediate corrective actions to improve efficiency, preventing bottlenecks and improving overall operational efficiency.

Choosing the right machine vision system

Choosing the right machine vision systems is vital to ensure optimal performance and meet the specific requirements of your application by understanding system capabilities.

Consider the following factors when selecting a right vision system. Several factors should be taken into account when choosing a machine vision system or systems.

Assessing application requirements

Assess the nature of your application and the specific inspection requirements. Determine the types of defects or anomalies you need to detect to inspect products, the desired level of accuracy and speed, and any specific industry regulations or standards to adhere to.

Evaluating physical constraints

Consider the physical constraints of your production environment. Evaluate the space available for installing multiple cameras, and lighting setups, as well as any environmental conditions that may impact system performance.

Budget considerations

Budget is another crucial aspect to consider. Cognex offers a range of vision systems with varying features and capabilities, each with different price points. Assess your budgetary constraints and align them with the specific needs of your application.

Different types of machine vision systems

Cognex offers a diverse range of inspection systems and vision systems designed to address various inspection and quality control needs. These include 2D vision systems, 3D vision systems, barcode readers, line scan cameras, and machine vision sensors.

2D vision systems: basic inspections and accuracy

2D vision systems are widely used for basic inspections, defect detection, and dimensional measurements. They provide efficient and accurate results for a wide range of applications.

3D vision systems: precision in depth perception

3D vision systems, on the other hand, allow for depth perception and enable precise measurements of object height, volume, and shape.

They are ideal for applications where 3D information is crucial, such as robotics, bin picking, packaging and surface inspection of packaging.

Advanced features and capabilities of machine vision systems

Machine vision systems offer a range of various devices with advanced features and capabilities, including real-time monitoring, that enhance their performance and expand their applications in various industries.

Machine learning and deep learning in machine vision systems

Machine vision systems utilize machine learning and deep learning technologies to improve inspection accuracy and adaptability.

Machine learning algorithms enable the system to learn from previous inspection data, identify patterns in data, and continuously improve upon its detection capabilities.

Advantages of deep learning algorithms

Deep learning algorithms, with their ability to analyze large datasets and extract intricate features manufactured products, enhance the first vision system's ability to recognize complex defects and contrast in products.

By leveraging a combination of these technologies, machine vision systems can achieve higher detection rates and lower false positive rates, improving overall inspection reliability.

3D Vision and Dimensional Measurement

Cognex optical systems incorporate 3D vision technologies to enable precise dimensional measurement and position and volume calculations.

By capturing depth information along with 2D images, the system and camera can accurately determine and measure the height, width focal length, shape and depth of objects, ensuring compliance with dimensional specifications.

This capability is particularly useful in applications such as robotics, where precise measurements are essential for tasks like pick and place operations.

With 3D vision capabilities, machine vision systems can accurately detect and classify objects based on their geometrical characteristics, providing enhanced inspection capabilities industrial robots and opening doors to a wide range of applications.

Surface Inspections and Texture Analysis

In addition to dimensional measurement, machine vision systems offer the ability to perform surface inspections and analyze complex textures using advanced image analysis techniques.

This technology allows the system to detect and measure surface defects, scratches, discolorations surface scratches, or other irregularities that may impact product quality.

By leveraging 3D vision and dimensional measurement capabilities, machine vision systems provide manufacturers with powerful tools to ensure product integrity, streamline processes, and meet quality standards.

Get product pricing

Cognex delivers the widest range of image-based factory automation and distribution products to help companies like you ensure error-free production, lower costs, and manage your supply chain