3D inspection of finished product and packaging

- Defect detection and surface validation

- Identification of cakes, individual cakes, candies and cookies

- Checking the height of the icing

- Checking volume and flatness

Find out more

Quality inspection of chocolate boxes

- Compliance with strict standards

- Identification of physical defects

- Identification of irregularities

Find out more

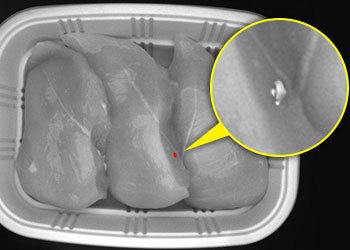

Automated Meat and Poultry Inspection

- Accuracy during visual classification of already packaged meat

- Visual identification of plastic or polystyrene foam

- Rapid detection of physical contamination elements

Find out more

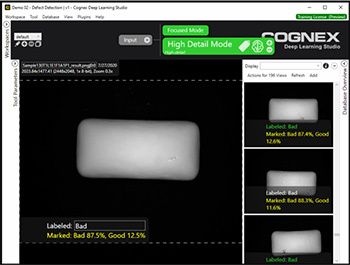

Chewing-gum inspection

- Detection of the subtlety and variability of possible defects as well as variation in acceptable appearance

- Achieving a level of quality that cannot be matched by other types of visual inspection

Find out more

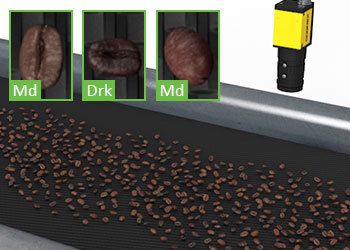

Inspection of coffee beans

- Identification of batches of grains confirmed before their inventory

- Verification of detection of physical contaminants, such as plant matter, stones, etc.

- Acceptance of variation in overall differences between coffee...

Find out more

Verification of packaging correspondence

- Localization and visual identification of food products before packaging

- Locate unnoticed variations such as angle, size and shade on objects

- Identification of food products and association of contents with their...

Find out more

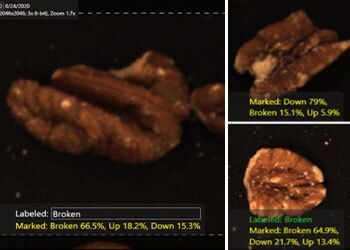

Inspection and sorting of nuts

- Distinction between acceptable forms and unacceptable states

- Rapid classification of nuts as acceptable or unacceptable

- Neither manual inspection nor other forms of machine vision can achieve the same speed and accuracy...

Find out more

Portioning inspection

- Detect volume and portion errors to maximize yield and reduce waste

- Measuring the volume of food products during assembly to check portion size

Find out more

Foreign body detection

- Intervention of contamination and foreign bodies, e.g. air pockets, dust, particles, hairs, etc.

- Defect detection in high-speed production environments

- Locate, analyze and classify complex contamination issues in...

Find out more

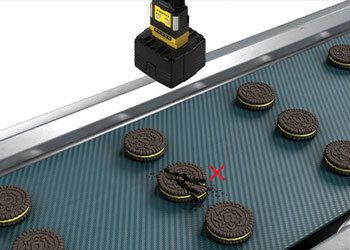

Verification of product uniformity

- Identification of packet patterns and stamps, despite changes in orientation, angle, lighting, etc.

- Rejection of damaged and broken products before packaging or distribution

Find out more