In-Sight 3800 vision system

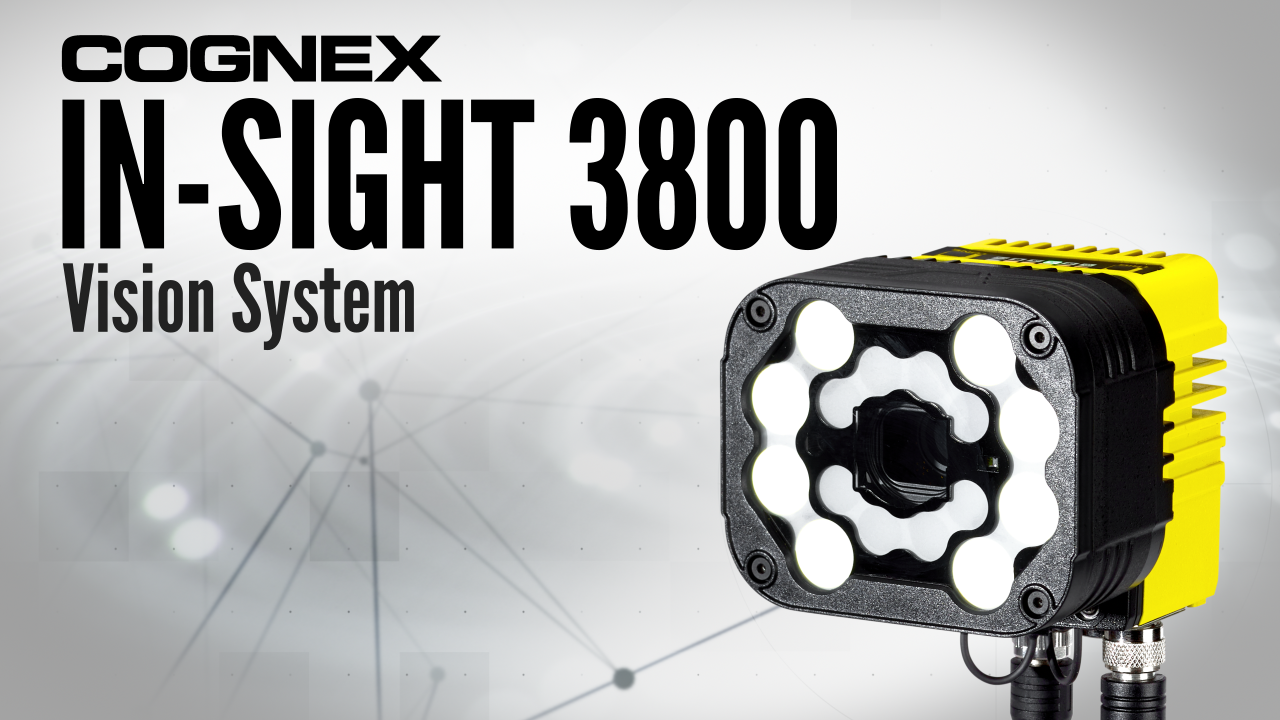

The Cognex In-Sight 3800 is a cutting-edge vision system that revolutionizes industrial automation and quality control processes. With its advanced technology fully integrated solution, and powerful capabilities, in sight 3800 has become a game-changer in the manufacturing industry. By combining precision imaging, intuitive and flexible software, robust spreadsheet interface and seamless integration, the vision system technology offers unmatched accuracy, efficiency, and reliability.

Understanding the Importance of Vision Technology in Industrial Automation

Vision technology, like the Cognex 3800 series, plays a pivotal role in industrial automation by providing reliable and accurate visual inspection capabilities. By using artificial intelligence and harnessing the power of advanced cameras, intelligent algorithms, artificial intelligence, and data processing, vision systems can detect even the most minute production defects and deviations.

This technology empowers manufacturers to automate their quality control processes, ensuring that every product meets rigorous standards by spreadsheet development environments. By leveraging machine vision products and technology, companies can minimize the risk of product recalls, enhance customer satisfaction, and ultimately boost their bottom line.

Key Features and Specifications of the Cognex In-Sight 3800

High-resolution image sensors

The Cognex 3800 series is fully integrated solution packed with a range of impressive features and specifications that make it a top choice for manufacturers seeking fully integrated solution to optimize their quality control processes. One of its standout features is its high-resolution image sensors, which enable it to capture incredibly detailed visuals of products and components passing through the inspection process. This high resolution system with this development process ensures that even the tiniest defects or imperfections are detected with exceptional precision.

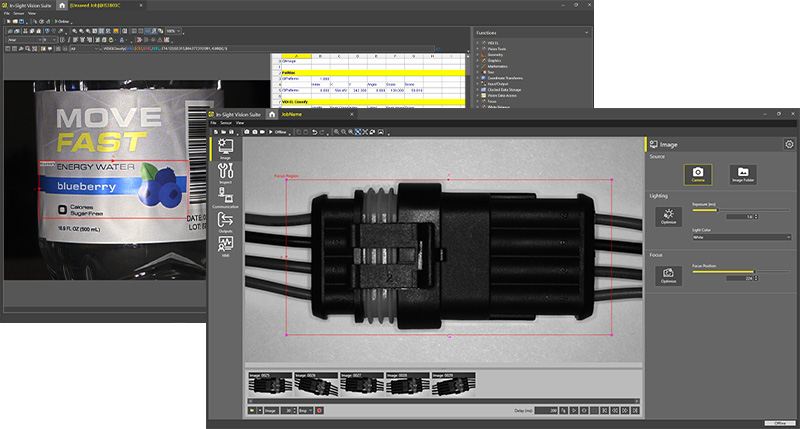

Advanced software

Another notable feature of the 3800 vision system is its advanced software, which provides intuitive job parameters, programming and analysis tools. These tools, way better than traditional rule based algorithms, allow users to easily set up and configure the sight 3800 according to their specific needs without requiring extensive technical expertise. The software in the sight 3800 vision system's intuitive interface makes it user-friendly and accessible, offering a spreadsheet interface enables finetuning and enabling operators to quickly adapt to the system and maximize its capabilities just a handful more.

Powerful imaging capabilities

In terms just a handful of specifications, this sight 3800 product, in the contrary of traditional rule based algorithms, boasts powerful imaging capabilities and lightning-fast processing speeds, ensuring real-time analysis, quality improvements and immediate feedback. Its robust construction, flexible software and industrial-grade design make it suitable for even the harshest job parameters, allowing it to withstand extreme temperatures, vibrations, and dust.

Enhance Quality Control and Inspection Processes

The in sight 3800 is engineered to revolutionize quality control and inspection processes, significantly improving the efficiency and accuracy of these critical operations. By leveraging the power of machine vision technology, this innovative system can detect defects, surface abnormalities, and measurement variations with unparalleled precision. Whether it's identifying cracks, scratches, or subtle color variations, the 3800 series ensures that no defect goes unnoticed.

With the sight 3800 vision system, manufacturers can achieve remarkable levels of quality control with spreadsheet development environments, improving customer satisfaction and brand reputation twice the processing speeds of previous systems. By reducing the likelihood of defective products reaching the market, companies can save significant costs associated with returns, recalls, and customer complaints.

Integrating the Cognex 3800 with existing automation systems

The seamless integration of edge learning technology in the Cognex 3800 In-sight series with existing automation systems is one of its standout features, enabling manufacturers to enhance their overall production efficiency and streamline their operations. The in sight 3800 vision system is a fully integrated edge learning technology, designed to effortlessly communicate and share data with other components of the production line, such as robotics, conveyors, and PLCs (Programmable Logic Controllers).

Leveraging Image Processing Capabilities of the Cognex 3800 In-sight series

The Cognex 3800 In-sight series leverages its advanced image processing powerful imaging capabilities to analyze visual data with exceptional accuracy and speed. It's spreadsheet interface enables finetuning are equipped with powerful algorithms, the in sight 3800 vision system can quickly and intelligently process images captured during the inspection and development process, enabling it to detect even the most subtle defects or irregularities.

The 3800 In-sight series's image processing capabilities encompass three vision tools with a variety of functionalities. These three vision tools include pattern recognition, color analysis, edge detection, and geometric measurements. The system can compare captured images against predefined templates or specifications of the in sight product line, allowing it to identify deviations from the expected standards. This ensures that every part in sight product line meets the desired quality criteria and reduces the risk of defective items reaching the market.

Additionally, the 3800 In-sight series provides multifunction, extensive vision toolset and customizable image processing options, empowering manufacturers to tailor the system's analysis parameters to their specific requirements and manufacturing process for inspection. This flexibility allows for precise and targeted, inspection applications, ensuring that the vision system adapts to the unique characteristics of different products inspection applications and manufacturing processes.

Real-world Applications of the Cognex 3800 In-sight series

The Cognex 3800 In-sight series is a versatile vision system that solve deterministic tasks and finds applications in various industries, offering tremendous value and solving unique challenges. This innovative technology enables manufacturers to enhance their quality control processes on high speed production lines, improve productivity, and achieve significant cost savings with flexible development options. Let's explore some real-world applications where vision products the 3800 In-sight series has proved its effectiveness.

Automotive

One key application is in the automotive industry, where the 3800 In-sight series is used for quality inspections of critical components such as engine parts, electrical connections, and body panels. By detecting defects or deviations from specifications, it ensures that only high-quality parts are integrated into vehicles, reducing the likelihood of failures or recalls.

Pharmaceutical

In the pharmaceutical industry, the 3800 In-sight series plays a vital role in ensuring product integrity and safety. It can perform inspections to verify accurate labeling, detect missing or misaligned packaging components, and identify contaminants. These inspections minimize the risk of medication errors, guarantee product authenticity, and uphold regulatory compliance.

Food and beverage

Another notable application is in the food and beverage industry, where the 3800 In-sight series can inspect packaging products, check for accurate labeling in sight products, and identify foreign objects in food products. By addressing these critical quality control measures in sight products, it supports food safety initiatives, prevents recalls, and protects consumer well-being.

Electronics

In the electronics industry, the 3800 In-sight series is utilized for verifying the correctness of component placement on printed circuit boards (PCBs) and detecting soldering defects. By ensuring the accuracy of components and the integrity of solder connections, it improves overall product quality and reliability.

Consumer goods

In the consumer goods industry, the 3800 In-sight series is utilized for inspecting packaging integrity and confirming product completeness. This ensures that consumer products such as cosmetics, household items, and personal care products are delivered to the market in optimal condition, meeting customer expectations.

Manufacturing

The manufacturing industry as a whole extensively uses the in sight 3800 vision system in various inspection applications too. It helps inspect product assembly, ensuring that components are correctly aligned, mounted, and fastened. The same 3800 vision system also facilitates quality checks during the production process, preventing defective products from progressing further high speed manufacturing lines and minimizing rework or customer complaints.