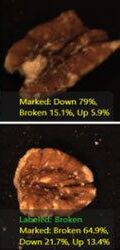

- Distinction between acceptable forms and unacceptable states

- Rapid classification of nuts as acceptable or unacceptable

- Neither manual inspection nor other forms of machine vision can achieve the same speed and accuracy in this task

Detect quality nuts to place on chocolates.