Enhance your quality inspection processes with our machine vision camera module, ensuring unmatched accuracy and seamless automation.

Explore our machine vision camera modules for embedded applications.

Get Started with Our Advanced Machine Vision Camera Module Today

Are you struggling with inspection reliability in your manufacturing process? Our advanced Machine Vision Systems offer a solution that not only enhances inspection accuracy but also streamlines your operations. With features like 3D depth mapping, you can ensure higher inspection reliability, leading to fewer errors and reworks. The ease of integration with existing systems means you won’t face the typical hassles of deployment. Join the ranks of satisfied manufacturers who have transformed their quality control process. Take action today and Contact Us.

- Higher inspection reliability with 3D depth mapping

- Faster throughput using LightBurst image acquisition

- Simplified deployment with integrated smart cameras

- Enhanced robot guidance for complex manufacturing tasks

How Our Machine Vision Camera Module Improves Manufacturing Quality

In today's competitive manufacturing landscape, leveraging technology is vital for quality assurance. Our machine vision camera module enhances manufacturing quality by providing accurate, real-time inspection capabilities. This ensures that products meet the highest standards before they reach consumers, instilling confidence in your production process. By addressing common quality inspection challenges, our solutions empower your team to act swiftly on quality control, ultimately driving higher customer satisfaction and loyalty.

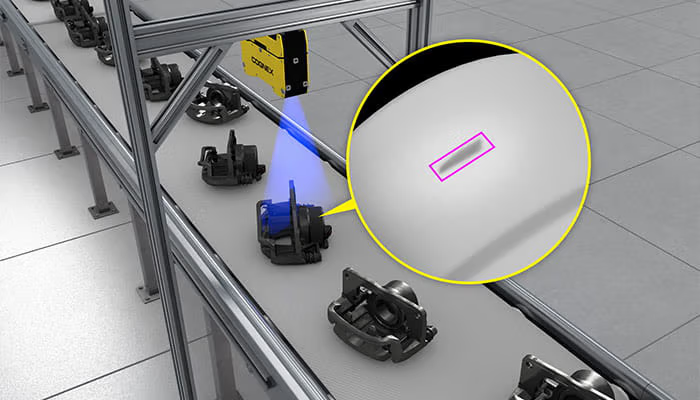

Increased Inspection Accuracy

Our machine vision camera module employs advanced 3D mapping technology that remains resilient under varying lighting and contrast conditions. For instance, in tests, our systems achieved a 25% increase in inspection accuracy compared to traditional 2D systems, effectively identifying subtle defects that would otherwise go unnoticed. This enhanced precision not only minimizes waste but also ensures compliance with stringent industry standards.

Automation and Speed Advantages

The rapid image acquisition capabilities of our all-in-one smart cameras significantly reduce setup and iteration times. By integrating multiple functionalities into a single device, manufacturers can streamline their quality control processes. This efficiency translates to faster production cycles, enabling your operations to meet increasing demand without compromising quality.

Applications of Machine Vision Camera Module in Industry

Machine vision camera modules are revolutionizing industries by automating inspections, enhancing process control, and ensuring consistent quality. In the automotive sector, these modules facilitate precise inspections of components, ensuring safety and compliance. For food & beverage, they detect defects and foreign objects, safeguarding consumer health. In general manufacturing, they streamline operations by enabling reliable quality checks, reducing human error, and increasing productivity. The advantages of implementing machine vision systems include higher inspection reliability, faster throughput, and easier deployment, ultimately leading to improved operational efficiency and cost savings.

Inspection and Process Control

Machine vision camera modules automate inspections, ensuring consistent quality throughout production lines. By utilizing advanced algorithms and real-time analysis, these systems maintain high standards of accuracy and reliability. They detect anomalies that human inspectors might overlook, significantly minimizing the risk of defects reaching customers. This automation not only enhances quality control but also streamlines processes, allowing manufacturers to focus on innovation and growth.

Robot Guidance and Complex Tasks

3D data from machine vision camera modules plays a crucial role in robot guidance and executing complex tasks. They enhance pick-and-place operations by providing accurate depth information, enabling robots to orient and locate components correctly. Moreover, they facilitate gap checks and precise measurements for welding and cutting applications, thereby improving the overall efficiency and safety of manufacturing processes. With these capabilities, manufacturers can significantly reduce errors and optimize their production workflows.

In-Sight 2000

In-Sight 2000 provides reliable image processing in a compact form for entry-level automation.

View Details

In-Sight 2000 Vision Sensors

The In-Sight 2000 Vision Sensors offer advanced processing power in a compact form.

View Details

DataMan 290

DataMan 290 excels in reading barcodes in a variety of conditions, making it ideal for standard applications.

View Details

Machine Vision Systems

Machine Vision Systems are essential tools that improve product quality and automate inspections in manufacturing. These...

View Details

In-Sight 2000 Mini Vision Sensors

The In-Sight 2000 Mini Vision Sensors provide precision in tight spaces for quality checks.

View Details

Vision Sensors

Vision sensors are pivotal in detecting features and verifying assembly in automated processes.

View Details

In-Sight 3800

In-Sight 3800 offers robust features for versatile inspection tasks in various industries.

View Details

Barcode Readers

Barcode Readers are vital for tracking products and managing inventory efficiently across multiple applications. They en...

View Details

DataMan 80

DataMan 80 delivers efficient scanning for various barcode types in demanding environments.

View Details

DataMan 390

DataMan 390 is designed for high-speed and high-resolution applications, ensuring reliable barcode reading.

View Details

In-Sight 2800

In-Sight 2800 is a high-performing vision system designed for complex manufacturing environments.

View DetailsFrequently Asked Questions About Machine Vision Camera Module

What is a machine vision camera module?

A machine vision camera module is an integrated imaging and processing device designed for automated inspection. It utilizes advanced algorithms to analyze images in real-time, ensuring high-quality control in manufacturing processes.

How does a machine vision camera module improve quality inspection?

Machine vision camera modules enhance quality inspection through 3D mapping and real-time analysis, which significantly improve accuracy and consistency in evaluating product quality.

Can the machine vision camera module be used in robot guidance?

Yes, machine vision camera modules are instrumental in robot guidance, facilitating tasks such as pick-and-place orientation and managing complex manufacturing processes.

What industries benefit most from machine vision camera modules?

Industries such as automotive, food & beverage, and general manufacturing see significant benefits from machine vision camera modules. For example, automotive manufacturers use these systems for quality control in assembly lines.

How easy is it to integrate a machine vision camera module into existing systems?

The integrated design of machine vision camera modules minimizes setup time and the need for custom coding, making it easier to incorporate them into existing systems.