As industries evolve, the integration of automation has become a cornerstone for success. Machine vision is at the forefront of this revolution, enabling manufacturers to enhance product quality and streamline processes. Understanding the basics of machine vision not only empowers you with the knowledge to make informed decisions but also sets the stage for unlocking unprecedented efficiencies in your operations.

Introduction to Machine Vision: Unlock the Future of Automation

Get Expert Insights on Machine Vision Basics Today

Discover how Machine Vision Systems can transform your manufacturing process. The challenges of maintaining high product quality and efficiency in inspections can be daunting. However, with expert resources and demos available, you can quickly grasp the basics of machine vision, empowering your operations with confidence. Don’t let complexity hold you back; take the first step towards automation and precision.

- Higher inspection reliability with 3D mapping technology

- Faster throughput using advanced LightBurst image acquisition

- Simplified deployment with all-in-one smart cameras

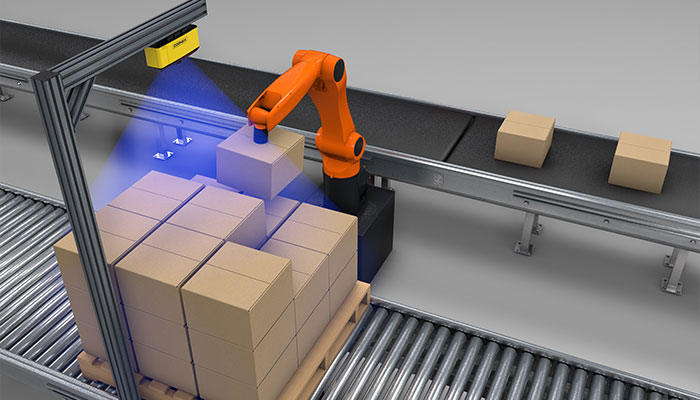

- Enhanced robot guidance for complex manufacturing tasks

Machine Vision Basics: How It Works and Why It Matters

Understanding machine vision is crucial for those looking to enhance their manufacturing processes. At its core, machine vision systems utilize advanced algorithms to automate inspections and ensure product quality. By leveraging real-time analysis, these systems not only improve inspection reliability but also facilitate faster throughput in production lines. With confidence, manufacturers can embrace machine vision basics as a pathway to streamline their operations and gain a competitive edge.

Core Components of Machine Vision Systems

Machine vision systems comprise several fundamental components: cameras that capture images, specialized lighting to ensure visibility, processors that analyze the data, and software algorithms that interpret the results. Each element plays a vital role in ensuring accurate inspections and measurements, making it essential for manufacturers to understand how these components work together.

Applications Across Industries

Machine vision systems find applications across various industries. In manufacturing, they are pivotal for inspection processes ensuring that products meet quality standards. Additionally, they play a crucial role in process control and robot guidance, enhancing efficiency and accuracy in production lines. By integrating machine vision, industries can significantly reduce errors and increase productivity.

Maximizing Performance with 3D Machine Vision

Imagine a manufacturing environment where precision and reliability are no longer just aspirations, but realities. 3D machine vision systems not only promise enhanced accuracy but deliver on that promise by outperforming traditional 2D systems. With accurate depth and orientation measurements, subtle part features are detected effortlessly, making your inspections more reliable than ever. This innovative technology ensures you can confidently tackle complex tasks, enhancing your operational efficiency. Curious to learn more about how these systems can transform your processes? Check out our offerings at Mécatronique Solutions.

- Accurate depth and orientation measurements

- Improved detection of subtle part features

- Robustness against lighting and position variations

- Enables complex robot guidance and inspection tasks

In-Sight 2000

In-Sight 2000 provides reliable image processing in a compact form for entry-level automation.

View Details

In-Sight 2000 Vision Sensors

The In-Sight 2000 Vision Sensors offer advanced processing power in a compact form.

View Details

DataMan 290

DataMan 290 excels in reading barcodes in a variety of conditions, making it ideal for standard applications.

View Details

Machine Vision Systems

Machine Vision Systems are essential tools that improve product quality and automate inspections in manufacturing. These...

View Details

In-Sight 2000 Mini Vision Sensors

The In-Sight 2000 Mini Vision Sensors provide precision in tight spaces for quality checks.

View Details

Vision Sensors

Vision sensors are pivotal in detecting features and verifying assembly in automated processes.

View Details

In-Sight 3800

In-Sight 3800 offers robust features for versatile inspection tasks in various industries.

View Details

Barcode Readers

Barcode Readers are vital for tracking products and managing inventory efficiently across multiple applications. They en...

View Details

DataMan 80

DataMan 80 delivers efficient scanning for various barcode types in demanding environments.

View Details

DataMan 390

DataMan 390 is designed for high-speed and high-resolution applications, ensuring reliable barcode reading.

View Details

In-Sight 2800

In-Sight 2800 is a high-performing vision system designed for complex manufacturing environments.

View DetailsReady to Elevate Your Production with Machine Vision?

Imagine a production line where quality is guaranteed, and inspections are seamless. Before implementing our Machine Vision Systems, many manufacturers struggled with inconsistent product quality and slow processes. Now, with our advanced technology, you can experience the confidence that comes with precise inspections and faster throughput. The bridge to your enhanced production efficiency is just a click away—contact us to explore how we can create a customized solution for your needs.

Frequently Asked Questions About Machine Vision

What is an introduction to machine vision?

Machine vision is a technology that enables automated visual inspections and measurements in manufacturing. It plays a crucial role in enhancing product quality by utilizing advanced algorithms for real-time analysis and process control.

What are the machine vision basics I should know?

Key components of machine vision systems include cameras, lighting, and software algorithms. These elements are crucial for effective image capture, illumination of the subject, and processing the visual data to derive meaningful insights.

How does 3D machine vision improve inspection?

3D machine vision enhances inspection by providing depth measurement and improved accuracy over traditional 2D systems. This allows for better detection of subtle features and ensures thorough evaluations of products.

Where can I learn more about machine vision applications?

For a deeper understanding and practical examples, visit our product pages and explore case studies that highlight the applications of machine vision in various industries.