Inspection accuracy is vital for packaging integrity. Discover how machine vision enhances reliability and precision in your inspections.

Benefits of machine vision in packaging inspection

Boost Packaging Quality with Advanced Machine Vision for Packaging Inspection

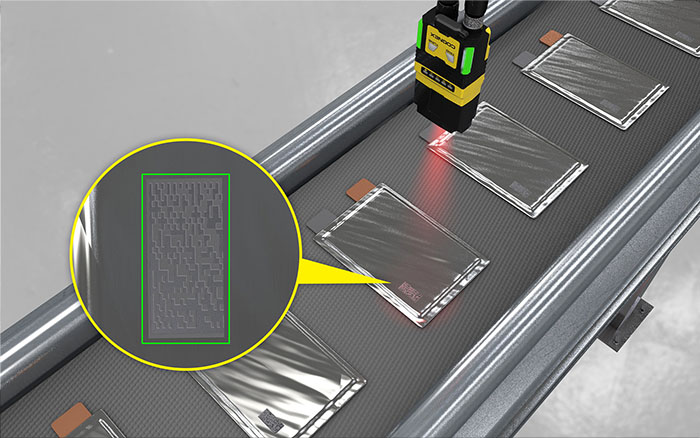

Are you struggling with inconsistent product quality and inspection accuracy? With Mécatronique Solutions' machine vision for packaging inspection, you can enhance your inspection process significantly. Our advanced machine vision systems utilize cutting-edge 3D smart cameras that ensure unmatched accuracy in detecting defects and variations. Imagine the confidence you'll feel knowing that your packaging quality is consistently top-notch, reducing waste and increasing customer satisfaction.

- Higher inspection reliability with 3D mapping technology

- Faster throughput using LightBurst image acquisition

- Simplified deployment with integrated smart cameras

- Enhanced robot guidance and complex task automation

Don't let subpar inspection processes hold your business back. Take action today and transform your packaging quality with our innovative machine vision solutions. Fill out the form below to learn more!

Get Started with Mécatronique Solutions

7 Reliable Techniques for Assessing Inspection Accuracy

In today's manufacturing landscape, ensuring inspection accuracy is paramount to maintaining product quality and operational efficiency. However, evaluating this accuracy can often present challenges. How can you ensure your inspection methods are not only effective but also cutting-edge? Here are seven proven evaluation methods to get you excited about enhancing your inspection processes. By leveraging machine vision for packaging inspection, you can achieve unparalleled precision and reliability.

- Visual Benchmarking Against Manual Inspection

- Use of Calibration Standards and Reference Samples

- Automated Defect Detection Rate Analysis

- Real-Time Statistical Process Control

- 3D Measurement Validation Using Depth Data

- Cross-Verification with Alternative Inspection Technologies

- Continuous Feedback Loop for System Improvements

Ready to dive deeper into these evaluation methods? Uncover detailed descriptions and insights on our product site! Explore how Mécatronique Solutions' machine vision systems can revolutionize your inspection processes by visiting this link.

How Machine Vision Systems Transform Packaging Inspection

Machine vision systems revolutionized packaging inspection by replacing slow and error-prone manual processes, significantly improving quality control.

Before: Manual and Inconsistent Inspections

Manual inspections often resulted in errors due to fatigue, oversight, and varying skill levels among inspectors. These inconsistencies could lead to defective products reaching customers, damaging brand reputation and trust. Additionally, slow throughput affected overall production efficiency, leaving manufacturers struggling to meet market demands.

After: Automated, Reliable, and Fast Inspection Processes

With the integration of machine vision for packaging inspection, manufacturers are now able to automate their quality control processes. This automation leads to higher inspection reliability, as the 3D mapping technology adapts to changes in contrast, color, lighting, and part position. The result? Faster throughput and more accurate measurements that ensure only top-quality products make it to market. Moreover, the deployment of these systems is streamlined, allowing for quick adaptation and minimal disruption in production.

Bridge: Deploying Integrated 3D Smart Cameras for Optimal Results

Deploying integrated 3D smart cameras simplifies the implementation of machine vision systems. These devices come equipped with dedicated tools that reduce the need for custom coding, making it easier for manufacturers to integrate them into their existing processes. The result is a seamless transition to automated inspections that not only enhance product quality but also boost operational efficiency.

In-Sight 2000

In-Sight 2000 provides reliable image processing in a compact form for entry-level automation.

View Details

In-Sight 2000 Vision Sensors

The In-Sight 2000 Vision Sensors offer advanced processing power in a compact form.

View Details

DataMan 290

DataMan 290 excels in reading barcodes in a variety of conditions, making it ideal for standard applications.

View Details

Machine Vision Systems

Machine Vision Systems are essential tools that improve product quality and automate inspections in manufacturing. These...

View Details

In-Sight 2000 Mini Vision Sensors

The In-Sight 2000 Mini Vision Sensors provide precision in tight spaces for quality checks.

View Details

Vision Sensors

Vision sensors are pivotal in detecting features and verifying assembly in automated processes.

View Details

In-Sight 3800

In-Sight 3800 offers robust features for versatile inspection tasks in various industries.

View Details

Barcode Readers

Barcode Readers are vital for tracking products and managing inventory efficiently across multiple applications. They en...

View Details

DataMan 80

DataMan 80 delivers efficient scanning for various barcode types in demanding environments.

View Details

DataMan 390

DataMan 390 is designed for high-speed and high-resolution applications, ensuring reliable barcode reading.

View Details

In-Sight 2800

In-Sight 2800 is a high-performing vision system designed for complex manufacturing environments.

View DetailsGet Started with Mécatronique Solutions’ Machine Vision Systems Today

Are you ready to elevate your manufacturing processes? With Mécatronique Solutions’ advanced Machine Vision Systems, you can ensure higher inspection reliability and faster throughput. Our systems are designed to adapt to various conditions, providing you with accurate measurements and robust performance. Don’t let outdated inspection methods hold you back. Experience the simplicity of deployment and maintenance with our integrated systems. As demand increases, so does the need for innovation—don’t miss out on this opportunity to stay ahead. Contact us today to see how our Machine Vision Systems can transform your operations!

Frequently Asked Questions About Machine Vision for Packaging Inspection

What is machine vision for packaging inspection?

Machine vision for packaging inspection refers to the use of advanced imaging technology and algorithms to automate the quality control process in manufacturing environments. This technology ensures that products meet specified standards by analyzing and inspecting packaging in real-time, enhancing efficiency and reliability.

How does machine vision improve inspection accuracy?

Machine vision systems enhance inspection accuracy through features such as 3D mapping, which provides depth and spatial awareness, allowing for precise measurements and defect detection. The speed of these systems ensures rapid processing of images, while their reliability reduces the likelihood of human error, resulting in higher quality assurance.

What industries benefit most from machine vision for packaging inspection?

Industries such as automotive, food & beverage, and general manufacturing are prime beneficiaries of machine vision for packaging inspection. These sectors rely on precise quality control to ensure product safety and compliance with industry standards, making machine vision systems vital.

Can machine vision systems integrate with existing production lines?

Yes, machine vision systems are designed for easy integration into existing production lines. With the use of smart cameras and plug-and-play functionalities, deployment is straightforward, allowing for minimal disruptions during installation.

Where can I learn more about implementing machine vision inspection systems?

You can learn more about implementing machine vision inspection systems by visiting our product pageand exploring our resources.