Agree on the importance of managing inventory effectively. We promise that with machine vision technology, you will gain practical steps to enhance your inventory management.

Assess Your Inventory Needs with Machine Vision Technology

Are you facing the problem of inventory shortages that threaten your operational efficiency? At Mécatronique Solutions, we understand that maintaining optimal stock levels is crucial for your business's success. Our inventory assessment process not only helps you identify critical stock levels accurately but also reduces costly stockouts and overstock situations. With proven machine vision technology for real-time tracking, you can enhance your operational efficiency through automation.

- Identify critical stock levels accurately

- Reduce costly stockouts and overstock situations

- Leverage machine vision technology for real-time tracking

- Enhance operational efficiency with automation

Understand How Machine Vision Technology Transforms Inventory Management

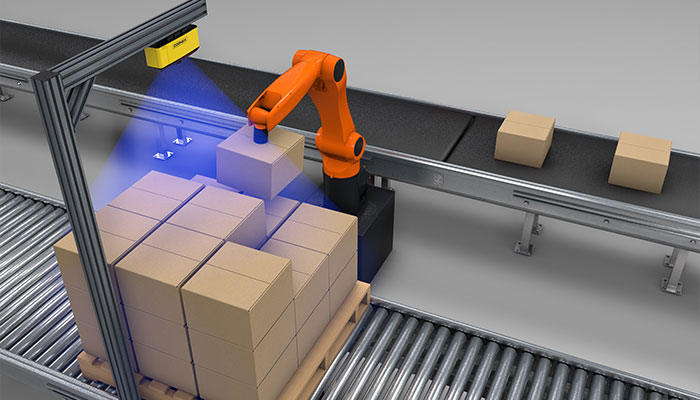

Machine vision technology is revolutionizing inventory management by providing real-time insights into stock levels, enhancing accuracy in inventory tracking, and reducing human error. By implementing this technology, businesses can streamline their operations, ensuring that they meet customer demands efficiently. With machine vision technology, you gain the empowerment to make informed decisions regarding inventory needs, minimizing storage costs and avoiding stockouts.

What is Machine Vision Technology?

Machine vision technology refers to the use of computer algorithms to interpret visual data from cameras and sensors. In the context of inventory management, it involves the automatic inspection and identification of products through imaging technology. As businesses face increasing inventory complexities, the need for such technology becomes imperative to maintain operational efficiency.

Key Benefits for Inventory Control

The integration of machine vision technology into inventory control systems offers numerous benefits: speed, accuracy, and seamless integration with existing barcode readers. By leveraging these features, businesses can significantly enhance their inventory management processes. For more details on optimizing your inventory management with barcode readers, visit our page at Mécatronique Solutions.

In-Sight 2000

In-Sight 2000 provides reliable image processing in a compact form for entry-level automation.

View Details

In-Sight 2000 Vision Sensors

The In-Sight 2000 Vision Sensors offer advanced processing power in a compact form.

View Details

DataMan 290

DataMan 290 excels in reading barcodes in a variety of conditions, making it ideal for standard applications.

View Details

Machine Vision Systems

Machine Vision Systems are essential tools that improve product quality and automate inspections in manufacturing. These...

View Details

In-Sight 2000 Mini Vision Sensors

The In-Sight 2000 Mini Vision Sensors provide precision in tight spaces for quality checks.

View Details

Vision Sensors

Vision sensors are pivotal in detecting features and verifying assembly in automated processes.

View Details

In-Sight 3800

In-Sight 3800 offers robust features for versatile inspection tasks in various industries.

View Details

Barcode Readers

Barcode Readers are vital for tracking products and managing inventory efficiently across multiple applications. They en...

View Details

DataMan 80

DataMan 80 delivers efficient scanning for various barcode types in demanding environments.

View Details

DataMan 390

DataMan 390 is designed for high-speed and high-resolution applications, ensuring reliable barcode reading.

View Details

In-Sight 2800

In-Sight 2800 is a high-performing vision system designed for complex manufacturing environments.

View Details5 Essential Steps to Avoid Inventory Shortages

Before implementing machine vision technology, businesses often face the anxiety of inventory shortages, leading to lost sales and dissatisfied customers. However, envision a future where your inventory is perfectly managed, ensuring you never miss a sale. This is achievable by following these five essential steps that utilize machine vision technology to create a secure inventory management system.

- Analyze historical sales data with machine vision insights

- Set accurate reorder points using real-time scanning

- Implement automated alerts via barcode readers

- Regularly audit inventory visually with machine vision cameras

- Train staff on technology to maintain process consistency

Frequently Asked Questions About Machine Vision Technology and Inventory Management

What is machine vision technology and how does it help inventory management?

Machine vision technology refers to the use of computer systems to interpret visual information from the world. This technology plays a crucial role in real-time inventory monitoring by allowing businesses to automatically track and manage stock levels, leading to improved efficiency and reduced human error.

Can machine vision technology integrate with existing barcode readers?

Yes, machine vision technology can seamlessly integrate with existing barcode readers, enhancing their functionality. This integration allows for greater accuracy in inventory management and streamlines processes, ultimately saving time and reducing costs.

How does machine vision technology reduce inventory shortages?

By continuously monitoring inventory levels and providing real-time alerts, machine vision technology helps prevent stockouts. This proactive approach ensures that businesses can maintain optimal inventory levels, ultimately reducing the risk of shortages.

Is specialized training required to use machine vision technology?

While specialized training can enhance the use of machine vision technology, many systems are designed for ease of adoption. Users can quickly learn to operate these systems, minimizing the need for extensive training.