Machine Vision Direct

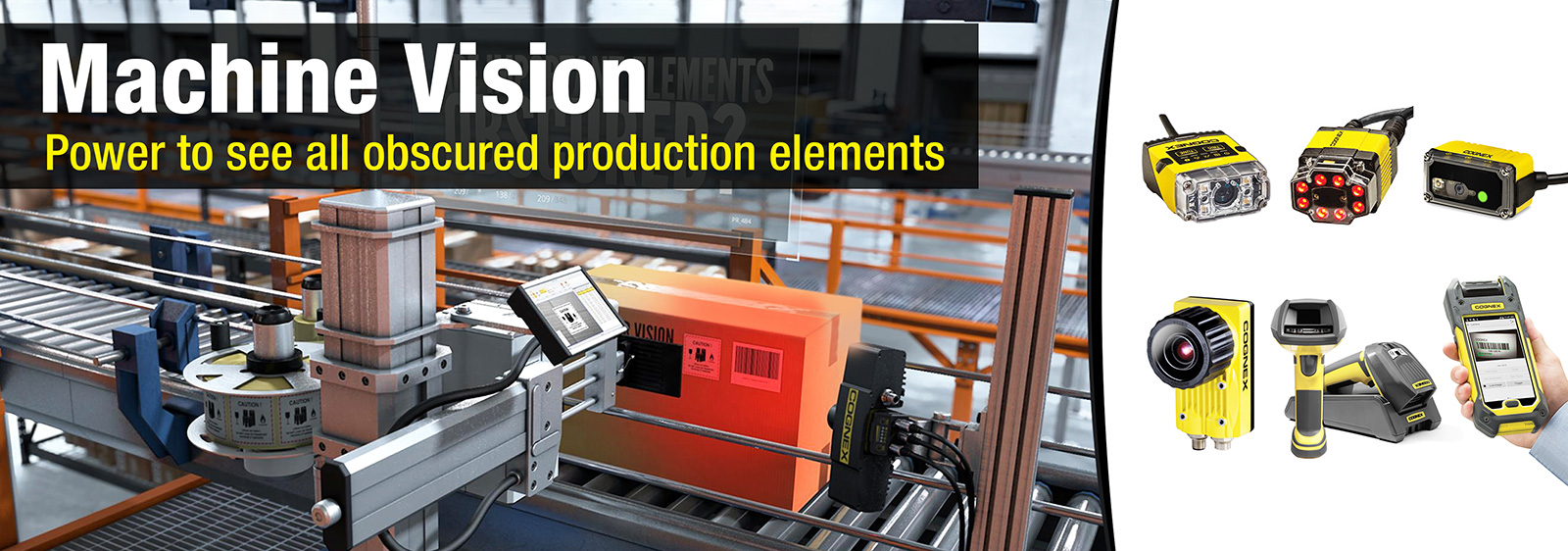

Machine vision direct technologies have emerged as essential tools across various industries, driving innovation and transforming the landscape of production and automation. By amalgamating advanced hardware, software algorithms, and image processing techniques, machine vision facilitate accurate data extraction from images and videos. Their application spans quality control, object recognition, and process optimization in diverse industrial sectors.

Features of Machine Vision direct

Quality Control

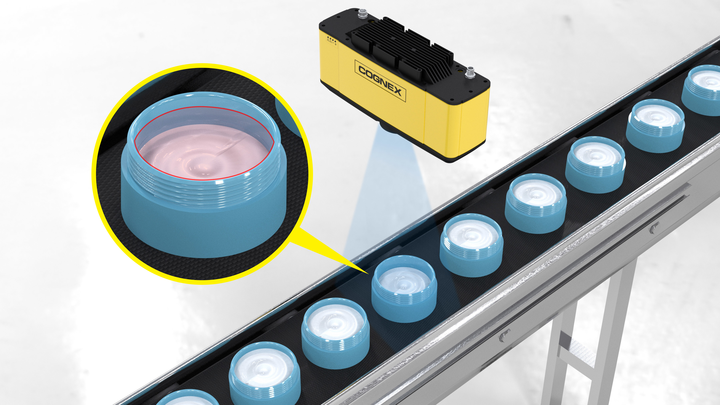

The implementation of machine vision direct for quality control significantly enhances product quality by accurately identifying even the minutest defects. These systems classify defects based on predefined criteria and offer manufacturers with insights for process improvements.

Additionally, its smart vision lights can automate rejection mechanisms to swiftly remove faulty light products from the light shop or production line, bolstering customer satisfaction and reducing rework expenses.

Accuracy and efficiency

Comparing machine vision to human vision underscores the distinct strengths and limitations of each. Machine vision excels in accuracy and efficiency, processing data rapidly and consistently. Conversely, perfect human vision outshines smart machine vision lab, lights they understand nuanced details, contextual information, and abstract concepts. While machines require programming to account for diverse scenarios, human adaptability remains unmatched.

Deep learning algorithms

Artificial intelligence has revolutionized machine vision direct systems, allowing for sophisticated image analysis, object recognition, and adaptive learning. Deep learning algorithms enable pattern recognition and anomaly detection, driving advancements in autonomous vehicles, security systems, and robotics. AI fosters continuous learning, refining performance over time for higher productivity.

Object Recognition with smart vision lights

With its smart vision lights, it can recognize objects, a core task in machine vision, employs diverse techniques such as image processing, pattern matching, and machine learning. Those midwest optical systems, with their prolonged liquid immersion with front illumination, backlight effect and economical price, facilitate accurate identification and classification of objects, empowering automation, quality control, and informed decision-making across a variety of industries.

Implementing Machine Vision direct technologies in Manufacturing

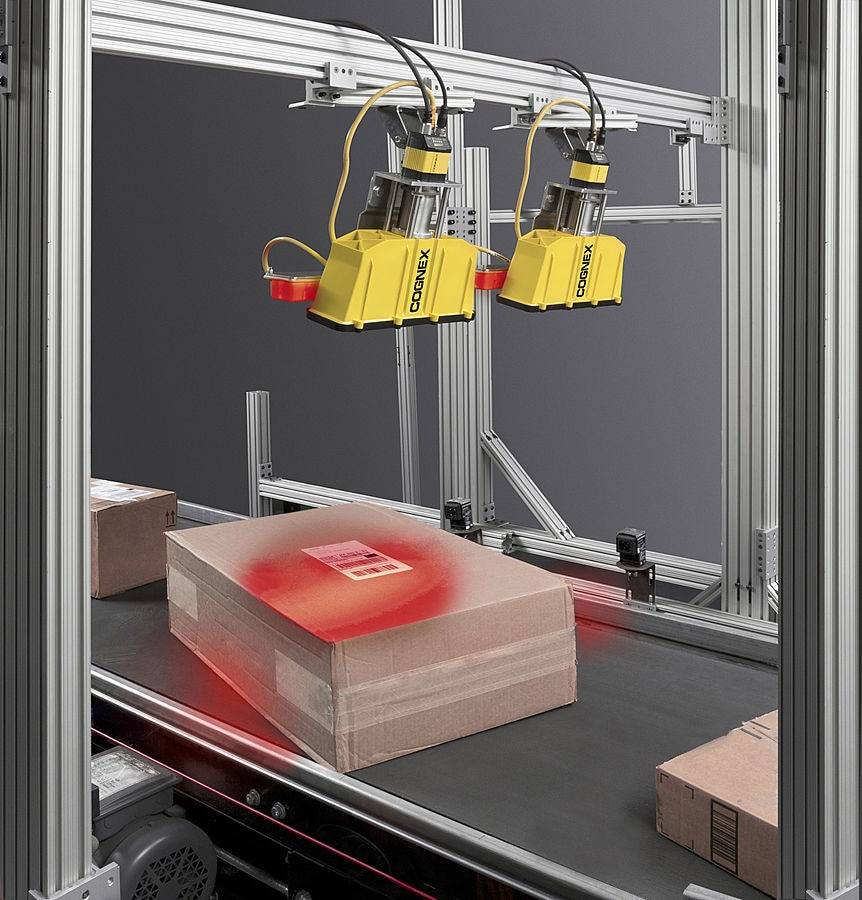

Vision-guided robotics

Machine vision direct integration in robotics drives efficiency and automation, enabling robots to make informed decisions in dynamic environments. Vision-guided robotics, midwest optical systems excel in diverse tasks like pick-and-place operations and quality control inspections. Collaborative robots, or cobots, leveraging machine vision direct, facilitate safe human-robot collaboration. Vision-based navigation empowers autonomous movement, particularly in logistics and warehousing.

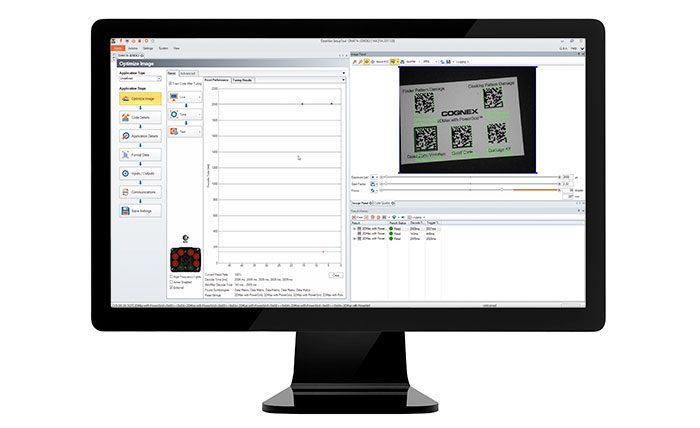

Algorithms and Image Processing

Machine vision direct algorithms, pivotal in the machine vision lab, encompass techniques like edge detection, segmentation, feature extraction, object tracking, and classification. These midwest optical systems, along with image processing techniques and smart vision lights, help engineers answer positively, optimize and improve visual data analysis, and deliver, enhancing applications in quality control, robotics, and medical imaging.

Machine Vision Direct in various industries

Healthcare

In the healthcare sector, these midwest optical systems plays a pivotal role in medical imaging, diagnostics, and patient care. It enhances disease detection, assists in treatment planning, and aids in remote diagnostics, revolutionizing access to healthcare in remote areas. Additionally, machine vision contributes to patient care by monitoring vital signs and improving safety measures.

Manufacturing

The manufacturing industry relies on machine vision direct for quality control, defect detection, and precision measurements in production processes. It is used in sectors like automotive, electronics, and consumer goods manufacturing.

Pharmaceutical and Medical Devices

In pharmaceutical manufacturing, machine vision is crucial for ensuring the quality and integrity of medical products, including pills, packaging, and medical devices. It helps detect defects and verifies labeling and packaging accuracy.

Food and Beverage

Machine vision plays a significant role in the food and beverage industry for quality inspection, sorting, and packaging. It ensures food safety, checks items for contaminants, and helps to create and maintain product consistency.

Case Study of Improving Quality Control in Electronics Manufacturing

A leading electronics manufacturer was struggling with quality control in its assembly phone line shop. The challenge was to accurately inspect and verify small details of components, filters and soldering points, which are critical for the functionality of their products.

The manual inspection process was time-consuming and prone to human error, leading to an unacceptable rate of defective products. The company needed to purchase a light solution that could automate the inspection process and deliver them with high precision and reliability, the best way possible. They were interested to find, choose and contact an authorized distributor depending on their capacities. They found and contact Mécatronique Solutions, they needed withstand illumination solutions.

With its smart vision lights, Machine Vision Direct's advanced backlight vision system was purchase, engineered and implemented in the production line. The mechanism included high-resolution cameras and sophisticated software capable of detecting and filters even minute flaws in components and soldering.

The introduction of Machine Vision Direct's technology led to a dramatic improvement in the quality control process. The midwest optical systems automated mechanism was able to inspect components at a much faster rate than manual methods, significantly increasing throughput. More importantly, the accuracy of machine vision direct inspections improved, resulting in a substantial reduction in the rate of defects. This not only saved costs associated with rework, filter kit and returns but also enhanced the company's reputation for quality in the market.

The data collected by the smart vision lights mechanism provided valuable insights into the light manufacturing process, allowing for further optimization and efficiency improvements. The company was also able to achieve better comply with industry standards and regulations thanks to the detailed inspection records maintained by the system, including smart vision lights.