Have you ever wondered how industries such as manufacturing, electronics, or machine vision maintain such precision and accuracy in their processes? The answer lies in the use of advanced technology, specifically laser profilers. These powerful tools have revolutionized the way we measure and analyze surfaces, offering high-resolution height measurements and ensuring the highest quality control standards.

Key Takeaways

- Laser scanner are highly accurate and versatile sensors with multiple benefits, ideal for in-line measurement applications across various industries.

- Laser triangulation is a reliable method of capturing 3D measurements, while exposure time. optimization ensures accuracy and reliability.

- With the right laser profiler tool for your application, you can maximize its potential through software solutions compatibility to ensure seamless data analysis and processing.

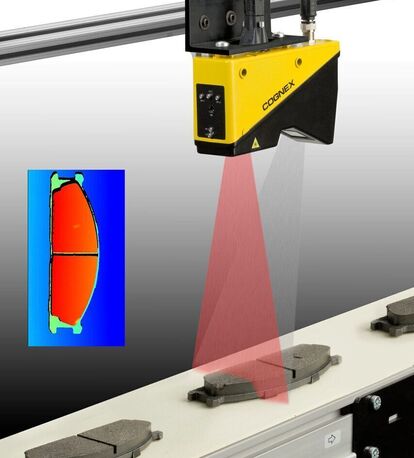

Laser profiler technology is a method of measuring displacements and surface heights utilizing high accuracy sensors and laser line triangulation principles. It enables the capture of precise distance measurements in a variety of applications, revolutionizing the way we assess and analyze surfaces.

Laser profilers have a wide range of applications across different industries, including gap measurement and inspection, material flatness measurement and inspection, and pipe size measurement and inspection. The AP820 series, for example, is suitable for a wide range of non-contact measurements and inspections, such as surface profile measurements, dimensions, deformations, flatness, gaps, volume, height, and thickness.

Selecting the appropriate laser profiler for your needs involves considering several factors. These include the desired resolution, accuracy, and compatibility with existing systems.

Consider the specific requirements of your target application and the types of measurements you need to perform. Also, evaluate the compatibility of the laser profiler solution with the software solutions you are using. The Z-Trak LP1 Laser Profiler, for example, is compatible with both Teledyne DALSA computer vision software and off-the-shelf 3rd party 3D image processing packages.

A careful assessment of your specific requirements and the capabilities of various laser profilers guarantees an investment in the right tool for your application and operation. This will ultimately lead to more accurate and efficient measurements, improving the overall quality service life and performance of your material and processes.

Intégration et compatibilité avec les solutions logicielles

Les profileurs laser, y compris les systèmes de profilage laser 3D, peuvent être intégrés à diverses solutions logicielles, telles qu'un logiciel tiers de traitement d'images 2D 3D et un logiciel de vision propriétaire, pour une analyse transparente des données et même un traitement 2D 3D. L’ensemble de cette configuration vous permet de maximiser le potentiel de votre système de profileur laser 3D et de l’intégrer facilement à vos systèmes existants.

Pour déterminer la compatibilité du profileur laser avec vos solutions logicielles, examinez la solution logicielle que vous utilisez actuellement et considérez les options logicielles de profilage disponibles pour identifier la meilleure approche d'intégration pour vos propres besoins en données de mesures de profil. En garantissant la compatibilité et l'intégration transparente des données de profil avec de nombreuses applications, vous pouvez libérer tout le potentiel de votre profileur laser et améliorer l'efficacité globale de vos processus de mesure.

Summary

In conclusion, laser profilers are powerful tools that offer high-resolution height measurements for various applications, providing more accurate measurement, and reliable data for industries such as manufacturing, handles targets from small electronics, and machine vision. Their large range of key features and benefits, such as adaptive laser control, optimized optical design, and compatibility with software solutions, make them indispensable assets in a wide range of industries.

As sensor technology continues to advance, the potential of laser profilers will only grow, further revolutionizing height measurement and production processes and enhancing the quality and efficiency of production across various industries. By understanding the technology behind these laser scanners and profilers and their applications, you can harness their full potential and stay ahead of the curve in today’s competitive production landscape.

Get product pricing

Cognex delivers the widest range of image-based factory automation and distribution products to help companies like you ensure error-free production, lower costs, and manage your supply chain